Note

Go to the end to download the full example code.

Diesel-type internal combustion engine simulation with gaseous fuel#

The simulation uses n-dodecane as fuel, which is injected close to top dead center. Note that this example uses numerous simplifying assumptions and thus serves for illustration purposes only.

Requires: cantera >= 3.0, scipy >= 0.19, matplotlib >= 2.0

import cantera as ct

import numpy as np

import matplotlib.pyplot as plt

Input Parameters#

# reaction mechanism, kinetics type and compositions

reaction_mechanism = 'nDodecane_Reitz.yaml'

phase_name = 'nDodecane_IG'

comp_air = 'o2:1, n2:3.76'

comp_fuel = 'c12h26:1'

f = 3000. / 60. # engine speed [1/s] (3000 rpm)

V_H = .5e-3 # displaced volume [m**3]

epsilon = 20. # compression ratio [-]

d_piston = 0.083 # piston diameter [m]

# turbocharger temperature, pressure, and composition

T_inlet = 300. # K

p_inlet = 1.3e5 # Pa

comp_inlet = comp_air

# outlet pressure

p_outlet = 1.2e5 # Pa

# fuel properties (gaseous!)

T_injector = 300. # K

p_injector = 1600e5 # Pa

comp_injector = comp_fuel

# ambient properties

T_ambient = 300. # K

p_ambient = 1e5 # Pa

comp_ambient = comp_air

# Inlet valve friction coefficient, open and close timings

inlet_valve_coeff = 1.e-6

inlet_open = -18. / 180. * np.pi

inlet_close = 198. / 180. * np.pi

# Outlet valve friction coefficient, open and close timings

outlet_valve_coeff = 1.e-6

outlet_open = 522. / 180 * np.pi

outlet_close = 18. / 180. * np.pi

# Fuel mass, injector open and close timings

injector_open = 350. / 180. * np.pi

injector_close = 365. / 180. * np.pi

injector_mass = 3.2e-5 # kg

# Simulation time and parameters

sim_n_revolutions = 8

delta_T_max = 20.

rtol = 1.e-12

atol = 1.e-16

Set up IC engine Parameters and Functions#

V_oT = V_H / (epsilon - 1.)

A_piston = .25 * np.pi * d_piston ** 2

stroke = V_H / A_piston

def crank_angle(t):

"""Convert time to crank angle"""

return np.remainder(2 * np.pi * f * t, 4 * np.pi)

def piston_speed(t):

"""Approximate piston speed with sinusoidal velocity profile"""

return - stroke / 2 * 2 * np.pi * f * np.sin(crank_angle(t))

Set up Reactor Network#

# load reaction mechanism

gas = ct.Solution(reaction_mechanism, phase_name)

# define initial state and set up reactor

gas.TPX = T_inlet, p_inlet, comp_inlet

cyl = ct.IdealGasReactor(gas)

cyl.volume = V_oT

# define inlet state

gas.TPX = T_inlet, p_inlet, comp_inlet

# Note: The previous line is technically not needed as the state of the gas object is

# already set correctly; change if inlet state is different from the reactor state.

inlet = ct.Reservoir(gas)

# inlet valve

inlet_valve = ct.Valve(inlet, cyl)

inlet_delta = np.mod(inlet_close - inlet_open, 4 * np.pi)

inlet_valve.valve_coeff = inlet_valve_coeff

inlet_valve.time_function = (

lambda t: np.mod(crank_angle(t) - inlet_open, 4 * np.pi) < inlet_delta)

# define injector state (gaseous!)

gas.TPX = T_injector, p_injector, comp_injector

injector = ct.Reservoir(gas)

# injector is modeled as a mass flow controller

injector_mfc = ct.MassFlowController(injector, cyl)

injector_delta = np.mod(injector_close - injector_open, 4 * np.pi)

injector_t_open = (injector_close - injector_open) / 2. / np.pi / f

injector_mfc.mass_flow_coeff = injector_mass / injector_t_open

injector_mfc.time_function = (

lambda t: np.mod(crank_angle(t) - injector_open, 4 * np.pi) < injector_delta)

# define outlet pressure (temperature and composition don't matter)

gas.TPX = T_ambient, p_outlet, comp_ambient

outlet = ct.Reservoir(gas)

# outlet valve

outlet_valve = ct.Valve(cyl, outlet)

outlet_delta = np.mod(outlet_close - outlet_open, 4 * np.pi)

outlet_valve.valve_coeff = outlet_valve_coeff

outlet_valve.time_function = (

lambda t: np.mod(crank_angle(t) - outlet_open, 4 * np.pi) < outlet_delta)

# define ambient pressure (temperature and composition don't matter)

gas.TPX = T_ambient, p_ambient, comp_ambient

ambient_air = ct.Reservoir(gas)

# piston is modeled as a moving wall

piston = ct.Wall(ambient_air, cyl)

piston.area = A_piston

piston.velocity = piston_speed

# create a reactor network containing the cylinder and limit advance step

sim = ct.ReactorNet([cyl])

sim.rtol, sim.atol = rtol, atol

cyl.set_advance_limit('temperature', delta_T_max)

Run Simulation#

# set up output data arrays

states = ct.SolutionArray(

cyl.thermo,

extra=('t', 'ca', 'V', 'm', 'mdot_in', 'mdot_out', 'dWv_dt'),

)

# simulate with a maximum resolution of 1 deg crank angle

dt = 1. / (360 * f)

t_stop = sim_n_revolutions / f

while sim.time < t_stop:

# perform time integration

sim.advance(sim.time + dt)

# calculate results to be stored

dWv_dt = - (cyl.thermo.P - ambient_air.thermo.P) * A_piston * \

piston_speed(sim.time)

# append output data

states.append(cyl.thermo.state,

t=sim.time, ca=crank_angle(sim.time),

V=cyl.volume, m=cyl.mass,

mdot_in=inlet_valve.mass_flow_rate,

mdot_out=outlet_valve.mass_flow_rate,

dWv_dt=dWv_dt)

Plot Results in matplotlib#

def ca_ticks(t):

"""Helper function converts time to rounded crank angle."""

return np.round(crank_angle(t) * 180 / np.pi, decimals=1)

t = states.t

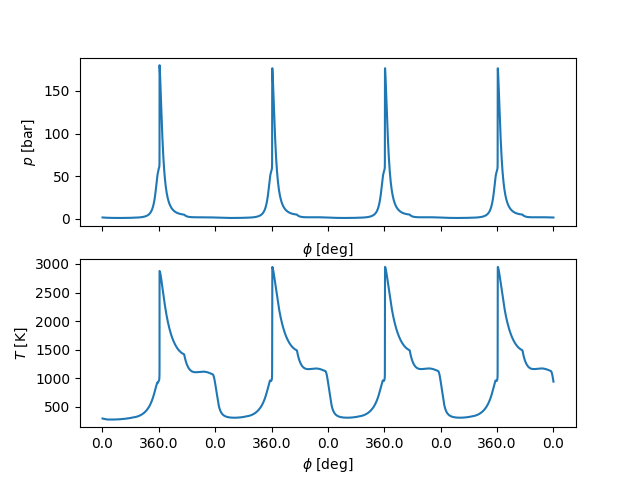

# pressure and temperature

xticks = np.arange(0, 0.18, 0.02)

fig, ax = plt.subplots(nrows=2)

ax[0].plot(t, states.P / 1.e5)

ax[0].set_ylabel('$p$ [bar]')

ax[0].set_xlabel(r'$\phi$ [deg]')

ax[0].set_xticklabels([])

ax[1].plot(t, states.T)

ax[1].set_ylabel('$T$ [K]')

ax[1].set_xlabel(r'$\phi$ [deg]')

ax[1].set_xticks(xticks)

ax[1].set_xticklabels(ca_ticks(xticks))

plt.show()

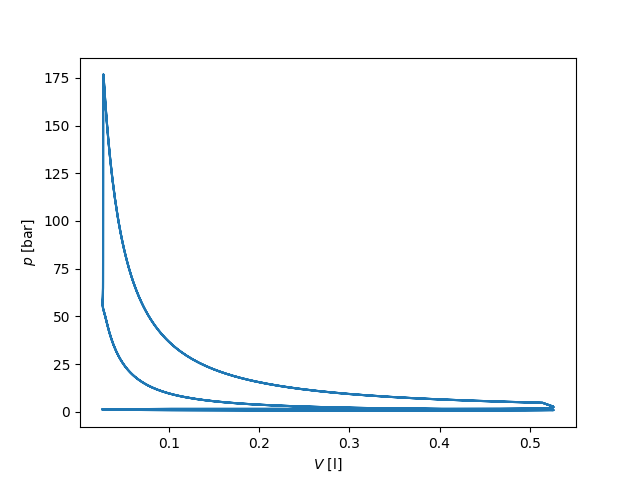

# p-V diagram

fig, ax = plt.subplots()

ax.plot(states.V[t > 0.04] * 1000, states.P[t > 0.04] / 1.e5)

ax.set_xlabel('$V$ [l]')

ax.set_ylabel('$p$ [bar]')

plt.show()

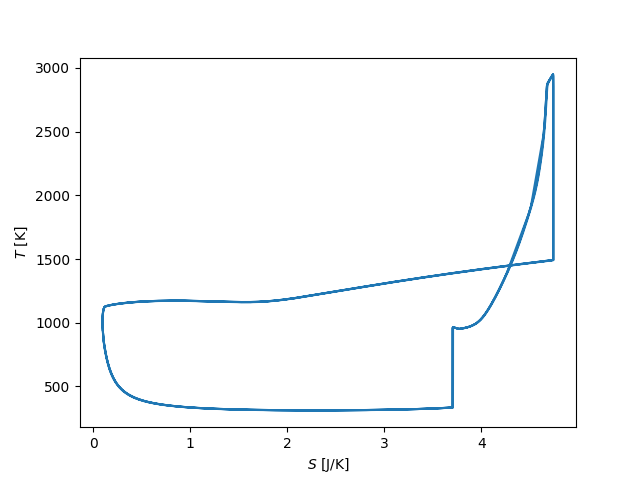

# T-S diagram

fig, ax = plt.subplots()

ax.plot(states.m[t > 0.04] * states.s[t > 0.04], states.T[t > 0.04])

ax.set_xlabel('$S$ [J/K]')

ax.set_ylabel('$T$ [K]')

plt.show()

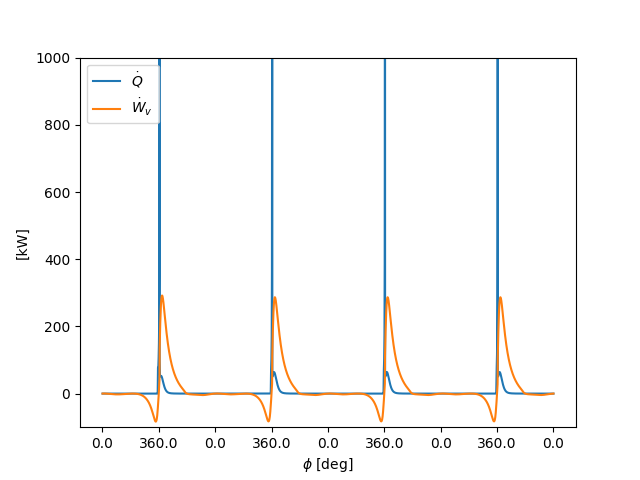

# heat of reaction and expansion work

fig, ax = plt.subplots()

ax.plot(t, 1.e-3 * states.heat_release_rate * states.V, label=r'$\dot{Q}$')

ax.plot(t, 1.e-3 * states.dWv_dt, label=r'$\dot{W}_v$')

ax.set_ylim(-1e2, 1e3)

ax.legend(loc=0)

ax.set_ylabel('[kW]')

ax.set_xlabel(r'$\phi$ [deg]')

ax.set_xticks(xticks)

ax.set_xticklabels(ca_ticks(xticks))

plt.show()

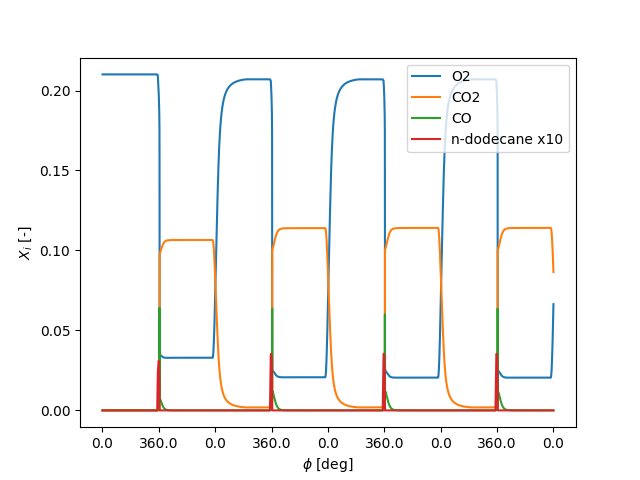

# gas composition

fig, ax = plt.subplots()

ax.plot(t, states('o2').X, label='O2')

ax.plot(t, states('co2').X, label='CO2')

ax.plot(t, states('co').X, label='CO')

ax.plot(t, states('c12h26').X * 10, label='n-dodecane x10')

ax.legend(loc=0)

ax.set_ylabel('$X_i$ [-]')

ax.set_xlabel(r'$\phi$ [deg]')

ax.set_xticks(xticks)

ax.set_xticklabels(ca_ticks(xticks))

plt.show()

Integral Results#

# heat release

Q = np.trapz(states.heat_release_rate * states.V, t)

output_str = '{:45s}{:>4.1f} {}'

print(output_str.format('Heat release rate per cylinder (estimate):',

Q / t[-1] / 1000., 'kW'))

# expansion power

W = np.trapz(states.dWv_dt, t)

print(output_str.format('Expansion power per cylinder (estimate):',

W / t[-1] / 1000., 'kW'))

# efficiency

eta = W / Q

print(output_str.format('Efficiency (estimate):', eta * 100., '%'))

# CO emissions

MW = states.mean_molecular_weight

CO_emission = np.trapz(MW * states.mdot_out * states('CO').X[:, 0], t)

CO_emission /= np.trapz(MW * states.mdot_out, t)

print(output_str.format('CO emission (estimate):', CO_emission * 1.e6, 'ppm'))

/home/runner/work/cantera/cantera/build/doc/samples/python/reactors/ic_engine.py:255: DeprecationWarning: `trapz` is deprecated. Use `trapezoid` instead, or one of the numerical integration functions in `scipy.integrate`.

Q = np.trapz(states.heat_release_rate * states.V, t)

Heat release rate per cylinder (estimate): 34.8 kW

/home/runner/work/cantera/cantera/build/doc/samples/python/reactors/ic_engine.py:261: DeprecationWarning: `trapz` is deprecated. Use `trapezoid` instead, or one of the numerical integration functions in `scipy.integrate`.

W = np.trapz(states.dWv_dt, t)

Expansion power per cylinder (estimate): 18.5 kW

Efficiency (estimate): 53.2 %

/home/runner/work/cantera/cantera/build/doc/samples/python/reactors/ic_engine.py:271: DeprecationWarning: `trapz` is deprecated. Use `trapezoid` instead, or one of the numerical integration functions in `scipy.integrate`.

CO_emission = np.trapz(MW * states.mdot_out * states('CO').X[:, 0], t)

/home/runner/work/cantera/cantera/build/doc/samples/python/reactors/ic_engine.py:272: DeprecationWarning: `trapz` is deprecated. Use `trapezoid` instead, or one of the numerical integration functions in `scipy.integrate`.

CO_emission /= np.trapz(MW * states.mdot_out, t)

CO emission (estimate): 8.8 ppm

Total running time of the script: (0 minutes 8.032 seconds)